ERW TUBE

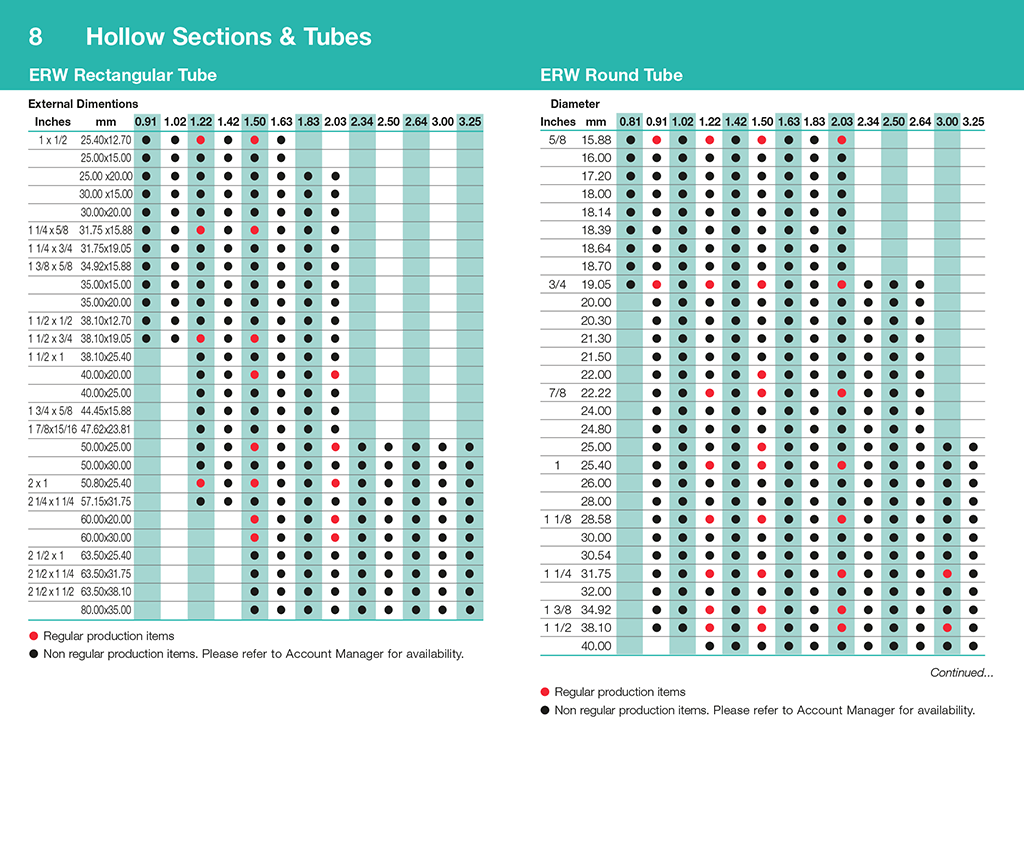

Electric Resistance Welded Tube (ERW) would typically be used in market sectors include Furniture, Fabrications, Display/Shop fittings, Storage/Racking, Automotive. ERW is available in tube or box section, the thin wall thickness of ERW can make it a cheaper alternative.

For prices and sizes available give us a call or fill in a request a quote form.

Common Uses of ERW Tubes

- Low Pressure Line Pipe

- Industrial / Agricultural Applications

- Fabrication

Why Choose South West Steel Supplies?

- Deliveries to all over the South West

- All Processing Carried Out for You

- Finest Quality Materials